Mini Review

Creative Commons, CC-BY

Creative Commons, CC-BY

The Use of the Bioleaching-Based Technique for the Treatment of Polluted Sulphide Tailings: A Short Review

*Corresponding author:Zeinab Piervandi, Department of Mining Engineering, Tarbiat Modarres University, Tehran, Iran.

Received:February 17, 2023; Published:March 23, 2023

DOI: 10.34297/AJBSR.2023.18.002456

Abstract

Bioleaching can be used for the treatment of toxic elements in sulphide mine-wastes as a newly developed, green and cost-effective technology. The bacterial activity causes the remarkable dissolution of elements compared with chemical methods. Researchers have employed bioleaching for the separation of trace elements from different sources. However, the transfer of toxic elements from contaminated solid wastes to the aquatic ecosystem can be minimized by the production of a biogenic passivation layer. It has resulted in a new perspective of microbial leaching application for the remediation of toxic soils. In this paper, bioleaching-based techniques for a reduction in the environmental pollution of mine tailings were reviewed.

Keywords: Bioleaching, Toxic elements, Contaminated mine-wastes, Treatment, Passivation

Introduction

Bioleaching is a low-cost and environmentally friendly method for the management of contaminated soils by decreasing and eliminating toxic elements contamination of sediments. In bioleaching, microbes mediate the leaching of trace elements from soil [1]. The application of Acidithiobacillus bacteria for heavy metals bioleaching from contaminated soil was investigated in recent works [2,3]. Manganese is recovered from its sources by bioleaching, which converts MnO2 into the low valence of Mn compounds [4]. In a recent study, Lysinibacillus fusiformis strain Lf as a strain of ureolytic bacteria with mineralization potential was separated from Cu–Ni mine waste in Xinjiang and used on a pilot scale for the tailings solidification and field conditions [5,6]. investigated the biotreatment of sulphide mine-wastes using bioleaching in the presence of Acidithiobacillus ferrooxidans. The results represented that the formation of biogenic jarosite during bioleaching led to a stable compound for the mine-waste less prone to dissolution in the acidic medium of mine tailings compared with the current techniques [2]. successfully performed the minimization of metals leaching from mine tailings due to the native bacteria activity, leading to the generation of a passivation layer. Accordingly, the passivation treatment acted oppositely to the current bioleaching method, in which metallurgists attempt to maximize the solubility of the elements. In the continuation of this paper, the details and mechanisms of the biotreatment of contaminated sulphide mine-wastes are presented.

Mechanisms of Biotreatment Reactions

The sulphide (bio)leaching is affected by the oxidation state of the Fe ions and competition between Fe2+ and Fe3+ [7]. The high amount of ferric ions prevents the ferrous in the sulphide’s surface from entering the bulk solution. The high concentration of Fe3+ ions functions as an inhibitory layer to slow down the leaching and shows a controlling effect on the )bio(dissolution of sulphide minerals, especially pyrite. Jarosite generation weight controlled the process by precipitating Fe3+ ions in the jarosite structure. From the start of the process, the ascending production of jarosite due to 1) the Fe-oxidizing bacteria activity on the sulphide minerals surface; 2) the addition of ferric ions to the process leads to the minimization of toxic elements dissolution [8].

Mechanisms of Toxic Elements Bio- Immobilization During Bioleaching

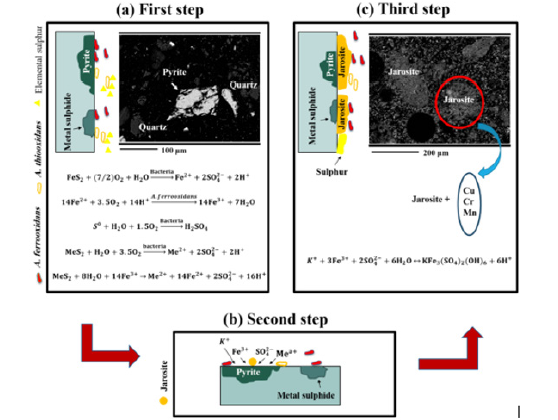

The mechanisms of toxic elements stabilization follow three essential stages during bioleaching-based treatment of sulphides (Figure 1): 1) the leaching of metal sulphides by acidophilic bacteria; 2) the nucleation of passivation on the surface of sulphides; 3) the co-precipitation of metal ions with jarosite in the bio-stabilization process [6].

Soil Structural Change by Biotreatment

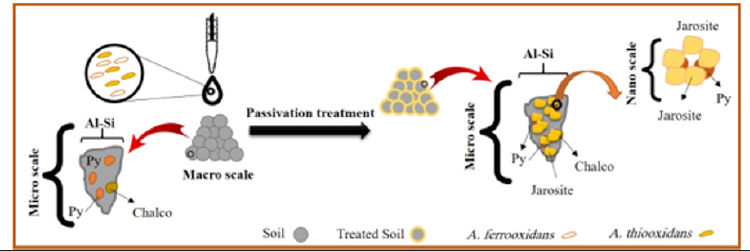

The schematic diagram of structural change in sulphide minewaste due to the passivation treatment using native bacteria is illustrated in (Figure 2). The primary soil of the Sarcheshmeh tailings sample (Kerman, Iran) is grey. After the bioleaching-based treatment, the surface compound of the soil changes into a new phase which prevents the dissolution of sulphide minerals and limits the solubility of metals. The micron-sized analysis of the treated soil shows the generation of small particles of biogenic jarosite as a protective structure covering the toxic tailings soil. Also, the nano-scale probe demonstrates the overlapping of surface passivation particles on pyrite and sulphide minerals [9] (Figure 1).

Data download

Reddits: Topics on the social networking site reddits contain content and comments on some topics(submissions) about abortion and gun control (Figure 1.1-Figure 1.2b).

Conclusion

The bioleaching-based techniques are the new treatment methods to minimize the toxicity of solid wastes. The mechanisms study shows that the effect of biogenic jarosite follows three main steps for the stabilization of heavy metals in sulphide tailings. The high concentration of Fe3+ ions produces a passivation layer in the bulk solution and plays an essential effect in controlling the sulphide leaching. The analyses of bio-treated sulphide tailings represent a fundamental change in the waste’s mineralogical structure, preventing the mobility of toxic elements (Figure 2).

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Fonti V, Dell Anno A, Beolchini F (2016) Does bioleaching represent a biotechnological strategy for remediation of contaminated sediments?. Science of the Total Environment 563-564: 302-319.

- Piervandi Z, Khodadadi Darban A, Mousavi S M, Abdollahy M, Asadollahfardi G, et al. (2019) Minimization of metal sulphides bioleaching from mine wastes into the aquatic environment. Ecotoxicology and Environmental Safety 182: 109443.

- Piervandi Z, Khodadadi Darban A, Mousavi S M, Abdollahy M, Asadollahfardi G, et al. (2021) Electrochemical and reactions mechanisms in the minimization of toxic elements transfer from mine-wastes into the ecosystem. Electrochimica Acta 388: 138610.

- Dey S, Tripathy B, Kumar M S, Das A P (2023) Ecotoxicological consequences of manganese mining pollutants and their biological remediation. Environmental Chemistry and Ecotoxicology 5: 55-61.

- He Z, Xu Y, Yang X, Shi J, Wang X, et al. (2022) Passivation of heavy metals in copper-nickel tailings by in-situ bio-mineralization: A pilot trial and mechanistic analysis. Sci Total Environ 838: 156504.

- Piervandi Z, Khodadadi Darban A, Mousavi S M, Abdollahy M, Asadollahfardi G, et al. (2020) Effect of biogenic jarosite on the bio-immobilization of toxic elements from sulfide tailings. Chemosphere 258: 127288.

- Rodríguez Y, Ballester A, Blázquez M L, González F, Munoz J A, (2003) New information on the pyrite bioleaching mechanism at low and high temperature. Hydrometallurgy 71: 37˗46.

- Piervandi Z (2021) Oral presentation in the Chicago University Congress: “Improvement and innovation in future industrial bioleaching” in the field of industrial bioleaching: 24.

- Piervandi Z (2022) Oral presentation in the UAE Congress: “Structural treatment in sulphide mine wastes through an inhibitory approach in bioleaching-based technique” 25th Global Biotechnology Congress: 25.

We use cookies to ensure you get the best experience on our website.

We use cookies to ensure you get the best experience on our website.